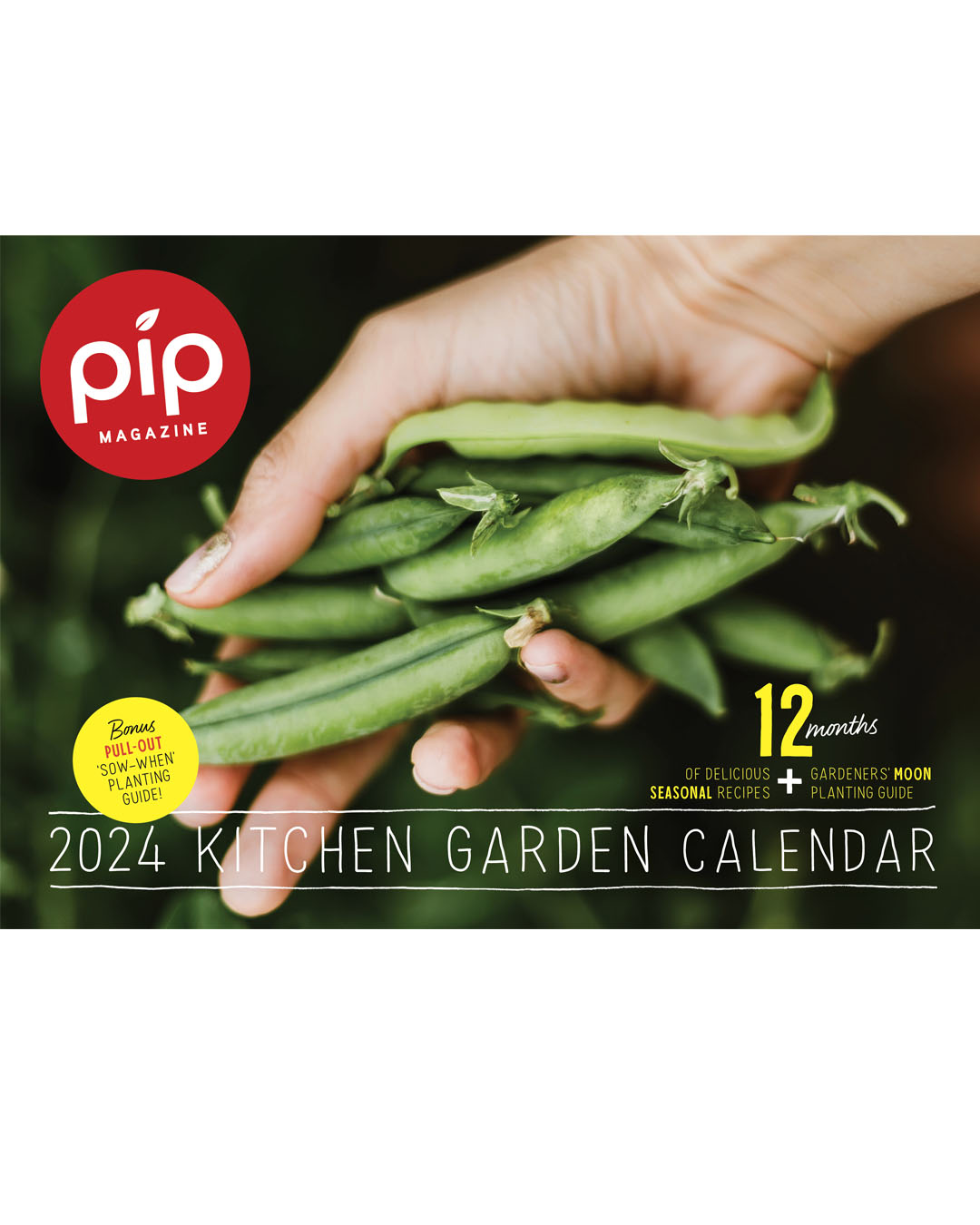

What’s in the new issue of Pip Magazine

Issue 31 is packed full of inspiration and information to nourish yourself and the planet. In this issue, we explore:

- Your complete guide to growing root vegies

- Understanding the best watering set up for your patch

- A collection of secret family preserving recipes

- Using spices to add warmth to your sweet desserts

- How to save your tomato seeds

- Meet the woman facing her death and challenging traditions

- A sustainable home built for intergenerational living

- Native plants for native birds

- Using jojoba oil to nourish your face, hair and body

And all our regular sections including seed saving, seasonal gardening advice, kid’s patch and more.

Latest Pip Inspiration

7 Ways To Detox Your Home

We bring you seven quick ways to detox your home to help improve your health.

How To Make Quick Compost

Want to start reaping the benefits of a compost pile for your garden… quickly? We show you how to…

4 Steps To Cleaning Garden Tools

Cleaning garden tools after you use them may seem like a lot of hard work, but it’s an important…

10 Must-Read Sustainability Books

We bring you a wrap up of the latest must-read sustainability books inspiring you to make a difference.

4 Watering Methods for Your Garden

Should you hand-water, install an irrigation system or plug in a sprinkler? We consider the best watering methods to…

Jojoba Skin Care Recipes

These jojoba skin care recipes will keep your dermis hydrated and nourished.

Garam Masala & Chocolate Chunk Cookies Recipe

Commonly associated with savoury dishes, spices can add a warmth and complexity to your sweet desserts… like these Garam…

Growing Root Vegetables

Root vegetables like carrots, beetroots, parsnips and radishes are staples in our kitchens and vegetable gardens. Let’s dig down…

Helping Create A Sustainable Future

Enjoy this and all our regular articles on foraging, seed saving, reducing waste and our ethical product reviews.

I just love my PIP subscription!!! When it arrives… I hide away with a cup of tea… after being engrossed in the contents. I launch out into the garden fuelled with inspiration and start creating a new patch! Thank you for keeping me going when my motivation runs dry. – Nikki

Finally! A magazine I can devour from cover to cover. Curled up on my lounge, coffee in hand, I turn off Netflix to read Pip. There are so many reasons to love this mag; I love the feel and texture of the recycled paper. I love the work of the cover artists, I love the articles. – Sandy

Pip magazine always brings a healthy dose of hope for humanity whenever it arrives. I absolutely love every issue and often refer back to them for ideas, recipes and advice. You have created something beautiful, hopeful and unifying. Thank you, thank you! – Esther

Pip Videos

Urban Foraging: A Beginner’s Guide: Video Series

Autumn is a great time for urban foraging. Here’s a handy guide to the fruits, nuts and weeds that can all be foraged.

How To Make Tomato Passata: Video Series

Here is our easy recipe to make tomato passata. This is a great way to preserve tomatoes so you can eat them when they…

How to Make Sourdough Bread: Video Series

Ready to take your sourdough bread to the next level? This recipe will create a beautiful artisan-style bread, and is a step up from…

How To Make Compost Tea (Homemade Liquid Fertiliser): Video Series

Learn how to make your own liquid fertiliser, sometimes called a compost tea. With just two ingredients you can create a great garden booster!

Join the Pip Magazine Community

Subscribe to the Pip newsletter to get regular ideas, information and inspiration to your inbox, and join our community on social media to connect with like minded people, to share ideas for a more sustainable future.

What you’ll get with your Pip subscription

- Get Pip Magazine delivered to your door 4 times a year (print)

- Access Pip Magazine any time, anywhere, on any device, so you can find it when you need it (Digital Subscription).

- Each issue is designed to help you nourish yourself, your community and the planet.

- Learn how to grow food, ferment, preserve, reduce waste, compost and more.

- Be inspired by stories of ordinary people doing extraordinary things.

Grow Your Own Food

How To Make Quick Compost

Want to start reaping the benefits of a compost pile for your garden… quickly? We show you how to make quick compost……

4 Steps To Cleaning Garden Tools

Cleaning garden tools after you use them may seem like a lot of hard work, but it’s an important part of treading…

4 Watering Methods for Your Garden

Should you hand-water, install an irrigation system or plug in a sprinkler? We consider the best watering methods to keep your plants…

Growing Root Vegetables

Root vegetables like carrots, beetroots, parsnips and radishes are staples in our kitchens and vegetable gardens. Let’s dig down into how to…

Subscriptions

Back Issues

Pip Products

Pip Podcasts

Pip Podcast #41: Alison Pouliot

In this Pip Podcast, we chat to ecologist, author and environmental photographer Alison Pouliot about the diverse world of fungi and its importance in our ecological networks.

Pip Podcast #40: Jane Hilliard

As overconsumption continues to drive the climate crisis, Tasmanian building designer, Jane Hilliard, is quietly trumpeting the idea that less is actually more.

Pip Podcast #39: Rod Angelo

In Pid Podcast #39, we talk to Rod Angelo (aka The Happy Farmer), about making his business viable by turning waste streams into inputs that would otherwise have cost money.

Pip Podcast #38: Helena Norberg-Hodge

Editor Robyn Rosenfeldt speaks with Helena Norberg-Hodge about the localisation movement, and why we need to be creating stronger local food systems and stronger connections within our community.

Business and Course Listings

Permaculture Courses

Learn about permaculture in a way that suits you. Browse through our permaculture course listings to find the course, time and location that best suits you.

Fair Traders Directory

Pip partners with brands which align with its values of earth care, people care and fair share. Ethical companies producing good quality products that don’t harm the planet, instead aim to improve it.

Courses Starting Soon

Ready to start your permaculture journey? Explore our permaculture courses starting soon to find the right course to get you growing now.